Research Scope

1. Soft Electronics and Beyond

Mechanically Deformable and Robust Devices and Sensors

Material Design: A general strategy to eliminate the mechanical strain on nonstretchable electronic materials while being stretched involves the engineering design from special mechanical structures or architectures. An alternative route to eliminating the burden of constructing dedicated architectures and the associated sophisticated fabrication processes is to build stretchable electronics from rubbery electronic materials, which have potential toward scalable manufacturing, high-density device integration, large strain tolerance.

Characterizations: Understanding the intrinsic material properties and corresponding mechanical properties is essential when developing soft electronics and related applications. Nanoindentation technique, SS testing, interfacial property analysis, surface structure analysis (SEM, TEM, 3D topography), chemical analysis, electrical analysis are often used to understand the underlying mechanism of the soft materials and to maximize the performance of the applications.

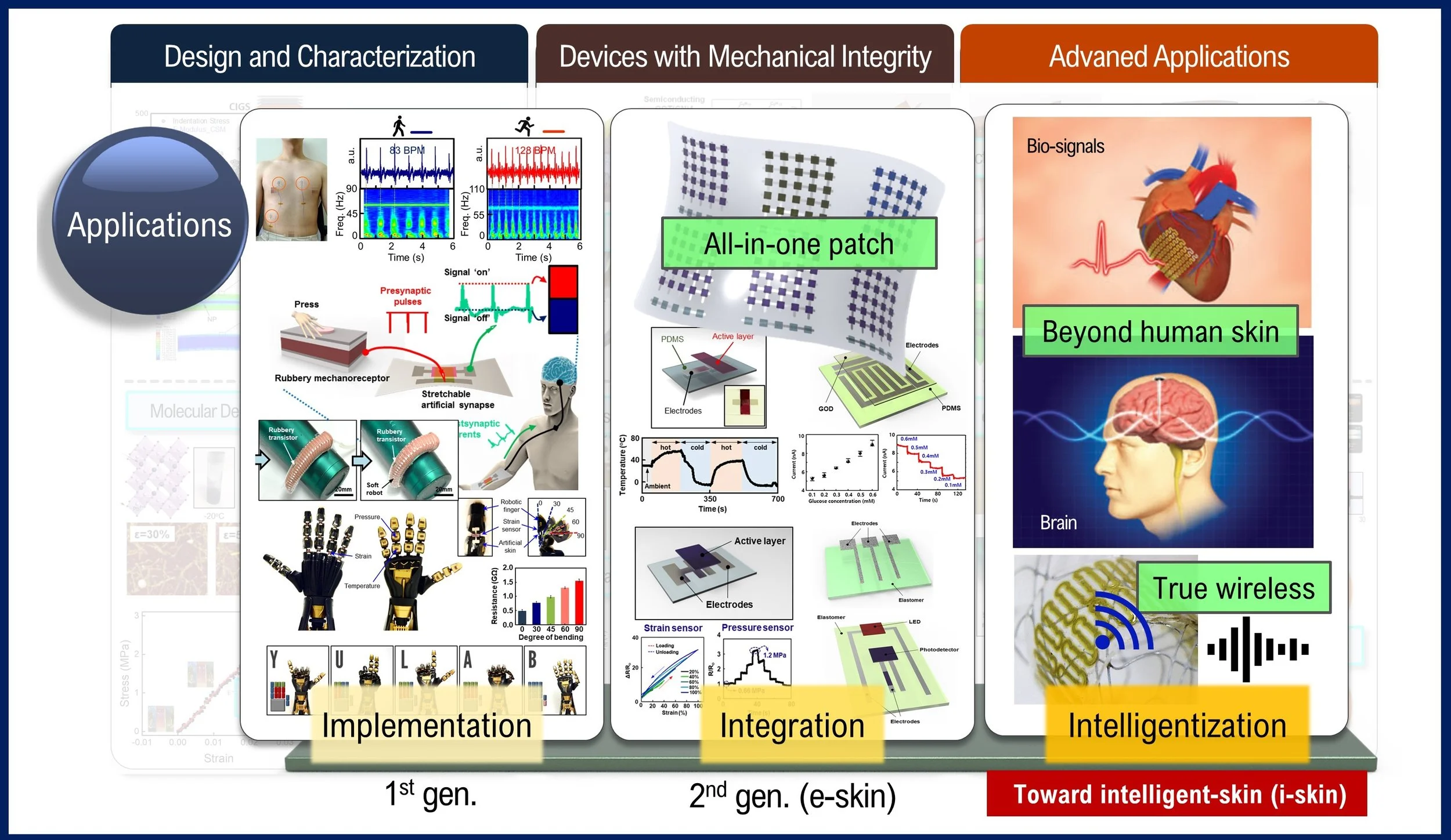

Applications: With a sophisticated design of the materials and a deep understanding of the material characterizations, we are very much open to various types of applications including physical sensors, optoelectronic devices, ICs, soft robots, smart gloves.

Toward Intelligentization

The 1st generation of soft electronics includes developing reliable soft materials with mechanical integrity. The researchers has focused on developing high-performance single unit devices with various type of detecting functionality. The 2nd generation of soft electronics can be described as “Integration”. With the rapid development of material patterning capability, an enormous amount of works has been conducted to integrate numerous sensors and operating circuits in the format of a single patch, which refers to electronic skin (e-skin).

Recently, soft devices are becoming more sophisticated and intelligent by combing neuromorphic devices, deep learning algorithms. There will be a lot of interest in developing intelligent soft electronics operating devices and sensors that have far more advanced capabilities and judgment skills than organic skin and internal organs.

2. Tribology

Friction and Wear Reduction

Prolonging the lifetime of the mechanical components: The development of infinite wear resistance technology requires an understanding of complex wear phenomena. In this regard, new wear theories are expected to emerge from this research. Particularly, the scientific contribution of ultra-low friction would be performance maximization of systems such as micro-systems, space and ultra-clean environments where conventional lubrication cannot be used. The results of this research are expected to aid in the improvement of precision system performance that utilizes micro-scale components as well as the development of practical techniques that may be used to protect the surface of products such as optical devices and flexible devices that have gained much attention in recent years.